We Supply Shredded Polycarbonate to the Middle East

SAFS Polycarbonate

What is Polycarbonate and where is it used?

Most people use polycarbonate products every day, even if they are not aware of it as Polycarbonate is everywhere!

Automotive

As Polycarbonate is durable and lightweight and plays an important role int he production of all vehicles. Its found in the Windows, headlights, door handles, radiator grills, interior and even the bumpers. Most cars are now produced with a very high percentage polycarbonate as its very light and durable and helps manufactures produce lighter and more efficient vehicles.

Electronics

As the perfect thermal insulator, it manages the heat produced by devices well, making it a desirable material for parts and components in electronic and electrical items

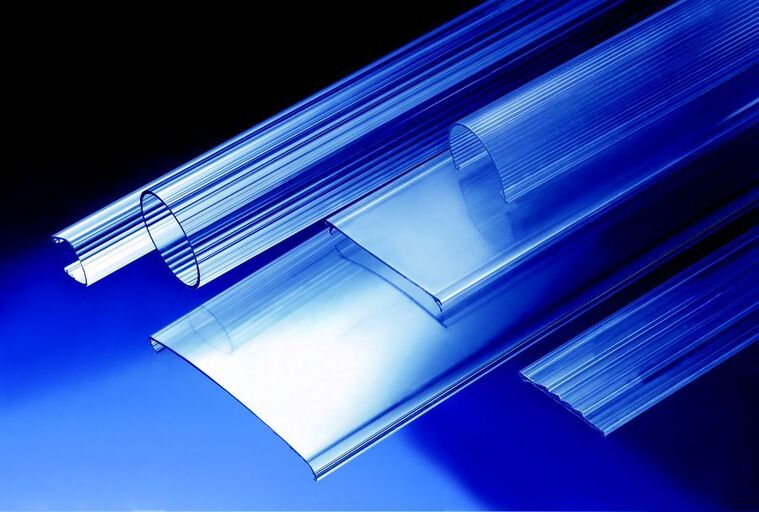

Electronic Media

As a naturally transparent amorphous thermoplastic, polycarbonate has a very useful ability in that it can internally transmit light almost as effectively as glass and also withstand impacts which makes it perfect for use in optical media. It is used almost exclusively in the production of DVD, Blu-ray, CD-ROM and many other types of media. Polycarbonate is used in either the cases or the media sub-straight of most DVDs, CDs and BluRay disks.

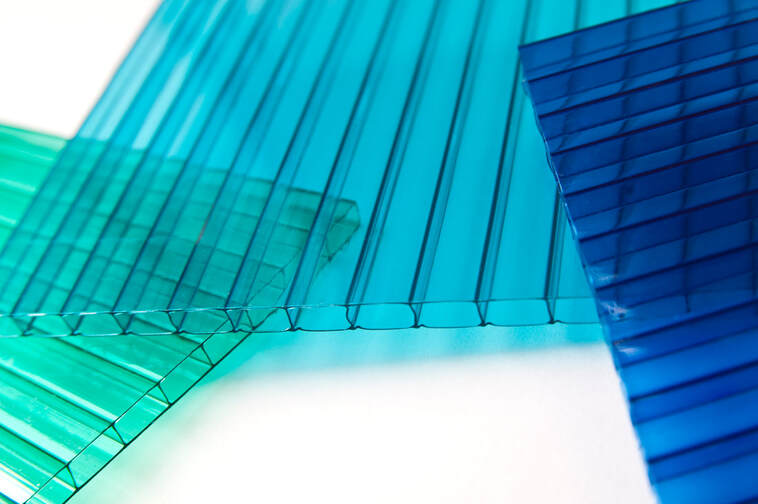

Outdoor Shelters

Any product that needs to use lightweight and durable materials can make use of polycarbonate. Any out door structures including Greenhouses or even Bus Shelters. Most outdoor shelters or even car park coverings must shield from rain, sun, snow, ice an in some locations even sandstorms or tornadoes. In some situations these shelters must even protect against vandalism and even fire.

Outdoor Signs

Polycarbonate is used to create conventional outdoor signs because the material is well known for its ability for light deflection and holding bright colors. For the more advanced LED signs, Polycarbonate has a high reflective index therefore it is the material of choice. Polycarbonate is also impact resistant and damage resistant, so physical damage is barely noticeable or easy to repair.

Playground Equipment

Playground equipment is an obvious use of Polycarbonate as it is light, durable, damage resistant and almost unbreakable. Along with the materials use with very bright colors and its ease of manufacture its the perfect choice.

The pliability of Polycarbonate allows it to be produced at room temperature without the problems of bending or cracking, it can even be re-molded or reformed without heat. This is know as its “amorphous” element. The “thermoplastic” part refers to the nature of polycarbonate and other similar plastics to become liquid at their melting point, making it perfect for easy injection molding and recycling.

SAFS Polycarbonate

What is Polycarbonate and where is it used?

Most people use polycarbonate products every day, even if they are not aware of it as Polycarbonate is everywhere!

Automotive

As Polycarbonate is durable and lightweight and plays an important role int he production of all vehicles. Its found in the Windows, headlights, door handles, radiator grills, interior and even the bumpers. Most cars are now produced with a very high percentage polycarbonate as its very light and durable and helps manufactures produce lighter and more efficient vehicles.

Electronics

As the perfect thermal insulator, it manages the heat produced by devices well, making it a desirable material for parts and components in electronic and electrical items

Electronic Media

As a naturally transparent amorphous thermoplastic, polycarbonate has a very useful ability in that it can internally transmit light almost as effectively as glass and also withstand impacts which makes it perfect for use in optical media. It is used almost exclusively in the production of DVD, Blu-ray, CD-ROM and many other types of media. Polycarbonate is used in either the cases or the media sub-straight of most DVDs, CDs and BluRay disks.

Outdoor Shelters

Any product that needs to use lightweight and durable materials can make use of polycarbonate. Any out door structures including Greenhouses or even Bus Shelters. Most outdoor shelters or even car park coverings must shield from rain, sun, snow, ice an in some locations even sandstorms or tornadoes. In some situations these shelters must even protect against vandalism and even fire.

Outdoor Signs

Polycarbonate is used to create conventional outdoor signs because the material is well known for its ability for light deflection and holding bright colors. For the more advanced LED signs, Polycarbonate has a high reflective index therefore it is the material of choice. Polycarbonate is also impact resistant and damage resistant, so physical damage is barely noticeable or easy to repair.

Playground Equipment

Playground equipment is an obvious use of Polycarbonate as it is light, durable, damage resistant and almost unbreakable. Along with the materials use with very bright colors and its ease of manufacture its the perfect choice.

The pliability of Polycarbonate allows it to be produced at room temperature without the problems of bending or cracking, it can even be re-molded or reformed without heat. This is know as its “amorphous” element. The “thermoplastic” part refers to the nature of polycarbonate and other similar plastics to become liquid at their melting point, making it perfect for easy injection molding and recycling.

We Supply Polyethylene Terephthalate (PET Plastic) to the Middle East

SAFS Pet Plastic

What is Polyethylene Terephthalate (PET ) and where is it used?

Polyethylene terephthalate (sometimes written poly(ethylene terephthalate) is commonly abbreviated as PET or PETE. However, strangely PET does not contain polyethylene!

These Plastics are some of the more commonly used for water bottles and other human consumable fluids. Unlike other types of plastics, polyethylene terephthalate is considered safe and is represented on water bottles with the number "1".

Perhaps one of the most important characteristics of PET plastics is their intrinsic viscosity. They can absorb water from their surroundings, which makes them hydroscopic.

PET plastics have a low coefficient of friction that makes them useful in various applications where other plastics cant be used.

PET plastics do not leak into their contents, making them a very important material for use in food storage.

PET plastics have an excellent level of wear resistance when compared to other plastics.

PET pastics have a high flexural modulus, making them very flexible.

PET plastics have a superior level of stability making them very durable, flexible and strong.

Common uses for polyethylene terephthalate (PET)

Polyethylene terephthalate is commonly used in bottles and other plastic containers, soda bottles, bakery products, water bottles, frozen food packaging, detergent, house hold cleaning and chemical storage.

Why do manufacturers use PET plastics when they could use many other materials?

They can be used repeatedly as recycling Polyethylene terephthalate is easy compared to other materials. PET plastics are transparent, making them very versatile for many container based applications. They are resealable as they are easy to mold into any shape and very flexible and are almost completely shatterproof. These types of plastics are one of the most inexpensive type of plastic to use. They can also be used as the base material for the production of fuel using high pressure and temperatures to convert the hydrocarbon rich material into diesel.

So recycling PET plastics really makes good sence.

SAFS Pet Plastic

What is Polyethylene Terephthalate (PET ) and where is it used?

Polyethylene terephthalate (sometimes written poly(ethylene terephthalate) is commonly abbreviated as PET or PETE. However, strangely PET does not contain polyethylene!

These Plastics are some of the more commonly used for water bottles and other human consumable fluids. Unlike other types of plastics, polyethylene terephthalate is considered safe and is represented on water bottles with the number "1".

Perhaps one of the most important characteristics of PET plastics is their intrinsic viscosity. They can absorb water from their surroundings, which makes them hydroscopic.

PET plastics have a low coefficient of friction that makes them useful in various applications where other plastics cant be used.

PET plastics do not leak into their contents, making them a very important material for use in food storage.

PET plastics have an excellent level of wear resistance when compared to other plastics.

PET pastics have a high flexural modulus, making them very flexible.

PET plastics have a superior level of stability making them very durable, flexible and strong.

Common uses for polyethylene terephthalate (PET)

Polyethylene terephthalate is commonly used in bottles and other plastic containers, soda bottles, bakery products, water bottles, frozen food packaging, detergent, house hold cleaning and chemical storage.

Why do manufacturers use PET plastics when they could use many other materials?

They can be used repeatedly as recycling Polyethylene terephthalate is easy compared to other materials. PET plastics are transparent, making them very versatile for many container based applications. They are resealable as they are easy to mold into any shape and very flexible and are almost completely shatterproof. These types of plastics are one of the most inexpensive type of plastic to use. They can also be used as the base material for the production of fuel using high pressure and temperatures to convert the hydrocarbon rich material into diesel.

So recycling PET plastics really makes good sence.

We Supply Acrylonitrile Butadiene Styrene (ABS) Plastic to the Middle East

What is ABS (Acrylonitrile Butadiene Styrene) plastic?

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer. It is a low-cost engineering thermoplastic that is easily machined, fabricated and thermoformed. This thermoplastic material has excellent chemical, stress and creep resistance. Thermoplastic refers to the way the material responds to heat. ABS offers a good balance of heat, dimensional stability, strength, chemical and abrasion resistance with advantageous electrical characteristics.

ABS properties

Easy to mold

High impact resistance

Strong with very good rigidity

Good chemical resistance

Electrical insulator

Mild heat resistance

Strain and abrasion resilience

Structural and dimensional stability

Good surface brightness

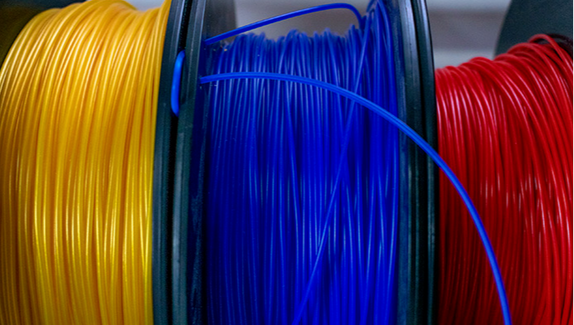

What can ABS plastic be used for?

ABS is very easy to machine and has a low melting point, making it particularly simple to manufacture products using injection molding or 3D printing.

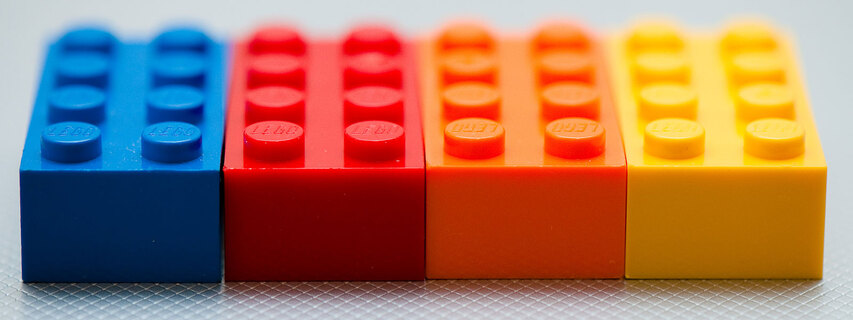

As ABS is resistant to scratches, general damage, impacts, vandalism and also has a strong resistance to chemical corrosion. Therefore it is the perfect plastic to be used in toys and high use or challenging environments.

ABS is also relatively inexpensive and normally priced between the cost of of and Polycarbonate Polypropylene.

What is ABS (Acrylonitrile Butadiene Styrene) plastic?

Acrylonitrile Butadiene Styrene (ABS) is an opaque thermoplastic and amorphous polymer. It is a low-cost engineering thermoplastic that is easily machined, fabricated and thermoformed. This thermoplastic material has excellent chemical, stress and creep resistance. Thermoplastic refers to the way the material responds to heat. ABS offers a good balance of heat, dimensional stability, strength, chemical and abrasion resistance with advantageous electrical characteristics.

ABS properties

Easy to mold

High impact resistance

Strong with very good rigidity

Good chemical resistance

Electrical insulator

Mild heat resistance

Strain and abrasion resilience

Structural and dimensional stability

Good surface brightness

What can ABS plastic be used for?

ABS is very easy to machine and has a low melting point, making it particularly simple to manufacture products using injection molding or 3D printing.

As ABS is resistant to scratches, general damage, impacts, vandalism and also has a strong resistance to chemical corrosion. Therefore it is the perfect plastic to be used in toys and high use or challenging environments.

ABS is also relatively inexpensive and normally priced between the cost of of and Polycarbonate Polypropylene.

We Also Provide Plastic Recycling Services

Plastic Recycling

Advanced Systems and Technology for all Types of Plastics

Recycling Plastics

Plastic is in containers, bottles, food packaging and even in make up. It is everywhere and, until recently, was pretty much ignored by everybody. Indeed throw away single use plastics are commonplace. However, plastic is as recyclable as it is versatile. The drawback is simple, not all types of plastics are created equal. So that anybody can easily identify the different types of plastics there is a number, known as an SPI Code, on all plastic containers. This provides all the information that you will ever need to regarding the biodegradability of the container or plastic and underlying composition.

Plastic is in containers, bottles, food packaging and even in make up. It is everywhere and, until recently, was pretty much ignored by everybody. Indeed throw away single use plastics are commonplace. However, plastic is as recyclable as it is versatile. The drawback is simple, not all types of plastics are created equal. So that anybody can easily identify the different types of plastics there is a number, known as an SPI Code, on all plastic containers. This provides all the information that you will ever need to regarding the biodegradability of the container or plastic and underlying composition.

Plastics & SPI Codes

1) Polyethylene Terephthalate (PETE or PET)

2) High Density Polyethylene (HDPE)

3) Polyvinyl Chloride (P or PVC)

4) Low-Density Polyethylene (LDPE)

5) Polypropylene (PP)

6) Polystyrene (PS)

7) Miscellaneous Plastics Polycarbonate (PC or Others)

1) Polyethylene Terephthalate (PETE or PET)

2) High Density Polyethylene (HDPE)

3) Polyvinyl Chloride (P or PVC)

4) Low-Density Polyethylene (LDPE)

5) Polypropylene (PP)

6) Polystyrene (PS)

7) Miscellaneous Plastics Polycarbonate (PC or Others)

SPI Code 1

Polyethylene Terephthalate (PETE or PET). These containers sometimes absorb odors and flavors from their contents. However, this is still a commonly used plastic for many household items and daily essentials.

SPI Code 2

High Density Polyethylene (HDPE). These products are very safe and are not known to leach into their contents. However, due to the risk of contamination, it's not safe to reuse an HDPE bottle as a food or drink container if it didn't originally contain some kind of edible substance.

SPI Code 3

Polyvinyl Chloride (P or PVC). This kind of plastic should not come in contact with food items as it is a toxic when ingested. PVC is in many everyday objects, but it's mostly used in the industrial and construction sectors.

SPI Code 4

Low-Density Polyethylene (LDPE). This plastic is very durable and flexible and does not release harmful chemicals into its contents. This makes it a safe choice for most products including food storage.

SPI Code 5

Polypropylene (PP). PP can be recycled, but is harder to process than PETE or HDPE. This type of plastic is very strong and durable sand can withstand higher temperatures. This type of plastic is used in things like take away containers and food packaging that can be used to re-heat food in a microwave.

SPI Code 6

Polystyrene (PS). PS can be recycled, but not very efficiently. The recycling of Polystyrene takes a lot of energy, therefore very few recycling plants accept it. This type of plastic is a huge environmental problem and presents unique challenges to the entire recycling industry.

SPI Code 7

Miscellaneous types of plastics, such as polycarbonate, that are not defined by the other six codes. Think of these items as plastics, but ones that don't conform to society's rules by fitting into a specific SPI code. These also cause huge problems and currently large volume of this type of plastics go directly to landfill.

Polyethylene Terephthalate (PETE or PET). These containers sometimes absorb odors and flavors from their contents. However, this is still a commonly used plastic for many household items and daily essentials.

SPI Code 2

High Density Polyethylene (HDPE). These products are very safe and are not known to leach into their contents. However, due to the risk of contamination, it's not safe to reuse an HDPE bottle as a food or drink container if it didn't originally contain some kind of edible substance.

SPI Code 3

Polyvinyl Chloride (P or PVC). This kind of plastic should not come in contact with food items as it is a toxic when ingested. PVC is in many everyday objects, but it's mostly used in the industrial and construction sectors.

SPI Code 4

Low-Density Polyethylene (LDPE). This plastic is very durable and flexible and does not release harmful chemicals into its contents. This makes it a safe choice for most products including food storage.

SPI Code 5

Polypropylene (PP). PP can be recycled, but is harder to process than PETE or HDPE. This type of plastic is very strong and durable sand can withstand higher temperatures. This type of plastic is used in things like take away containers and food packaging that can be used to re-heat food in a microwave.

SPI Code 6

Polystyrene (PS). PS can be recycled, but not very efficiently. The recycling of Polystyrene takes a lot of energy, therefore very few recycling plants accept it. This type of plastic is a huge environmental problem and presents unique challenges to the entire recycling industry.

SPI Code 7

Miscellaneous types of plastics, such as polycarbonate, that are not defined by the other six codes. Think of these items as plastics, but ones that don't conform to society's rules by fitting into a specific SPI code. These also cause huge problems and currently large volume of this type of plastics go directly to landfill.

|

Safs Plastic Recycling

The plastic reclamation and processing industry has to create more opportunities to recycle plastics. At Safs Plastic Recycling we strive to expand the recycling of plastic material by working with state of the art technology and waste management officials. This approach has allowed us to take a fresh look at the entire process and enhance the collection and reclamation programs to increase the efficiency and yield for as many plastics as possible. |